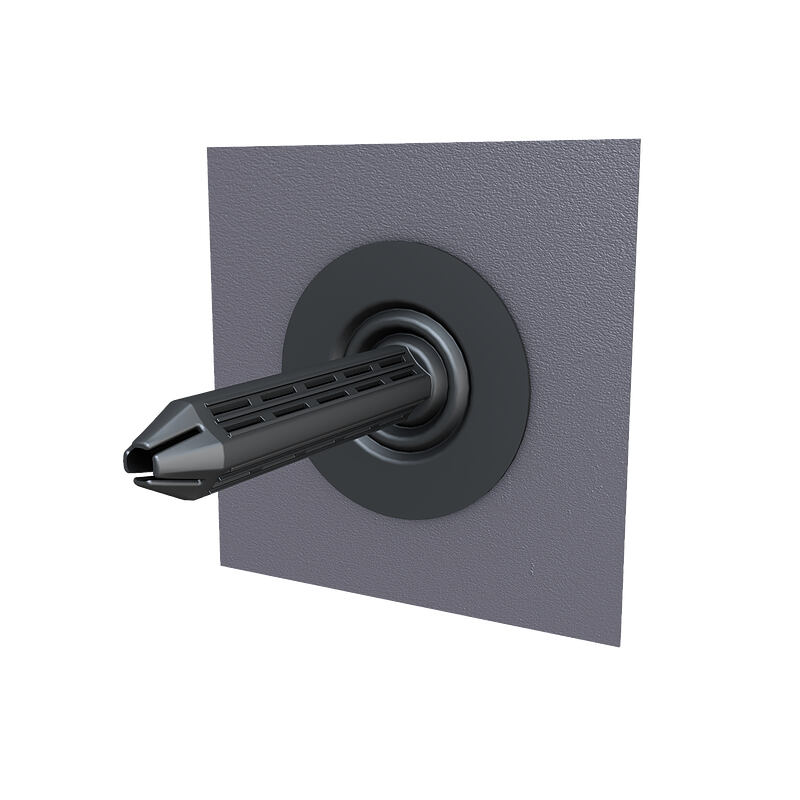

Cables and pipes are often installed in buildings retrospectively. This is usually necessary in existing buildings that are undergoing renovation. If no openings were provided for the installation of cables and pipes during the construction phase, then a core drilling is necessary. In order to protect the building from water and gases even after drilling through the wall, various sealing solutions have been developed for existing buildings. One of these is the membrane injection system, or short: MIS. The MIS system is suitable for sealing all types of walls, as well as for most wall sealing solutions.

Membrane Injection System

Membrane injection method

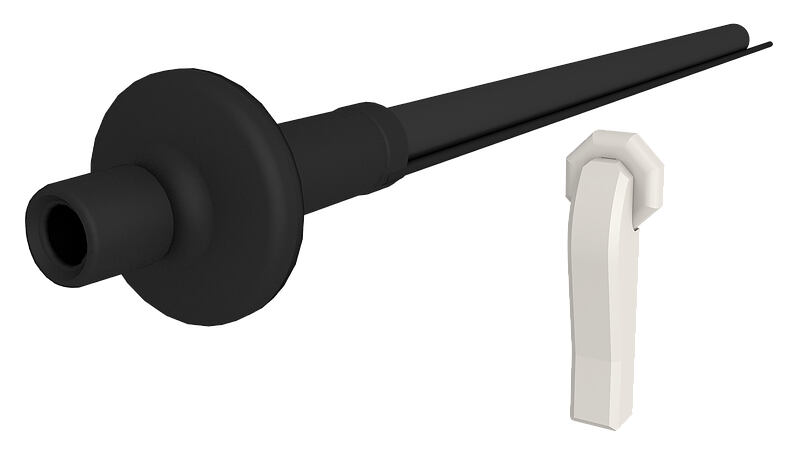

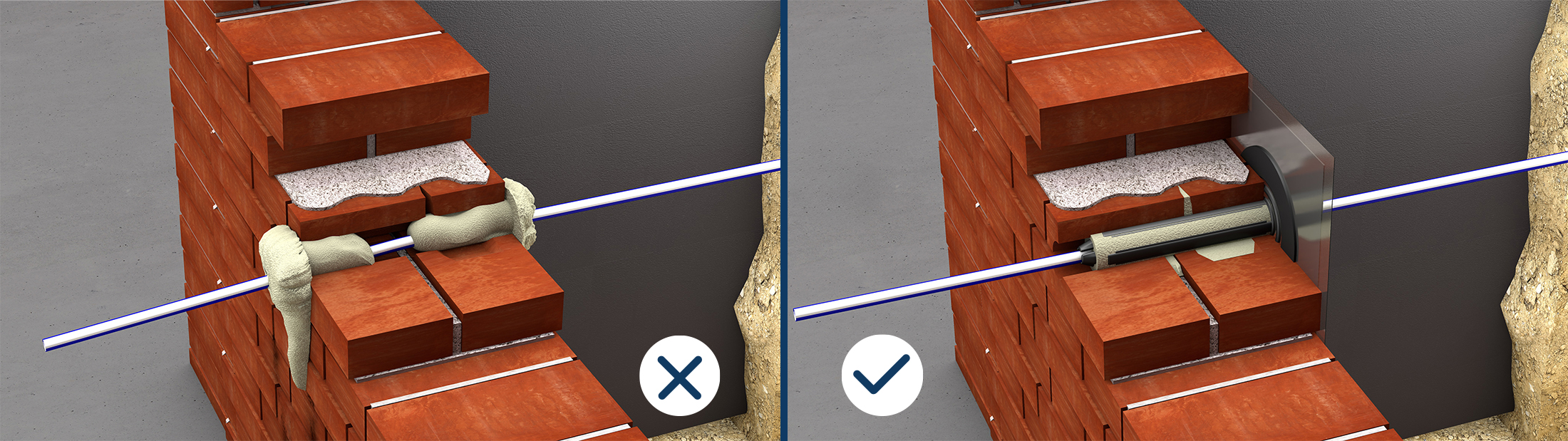

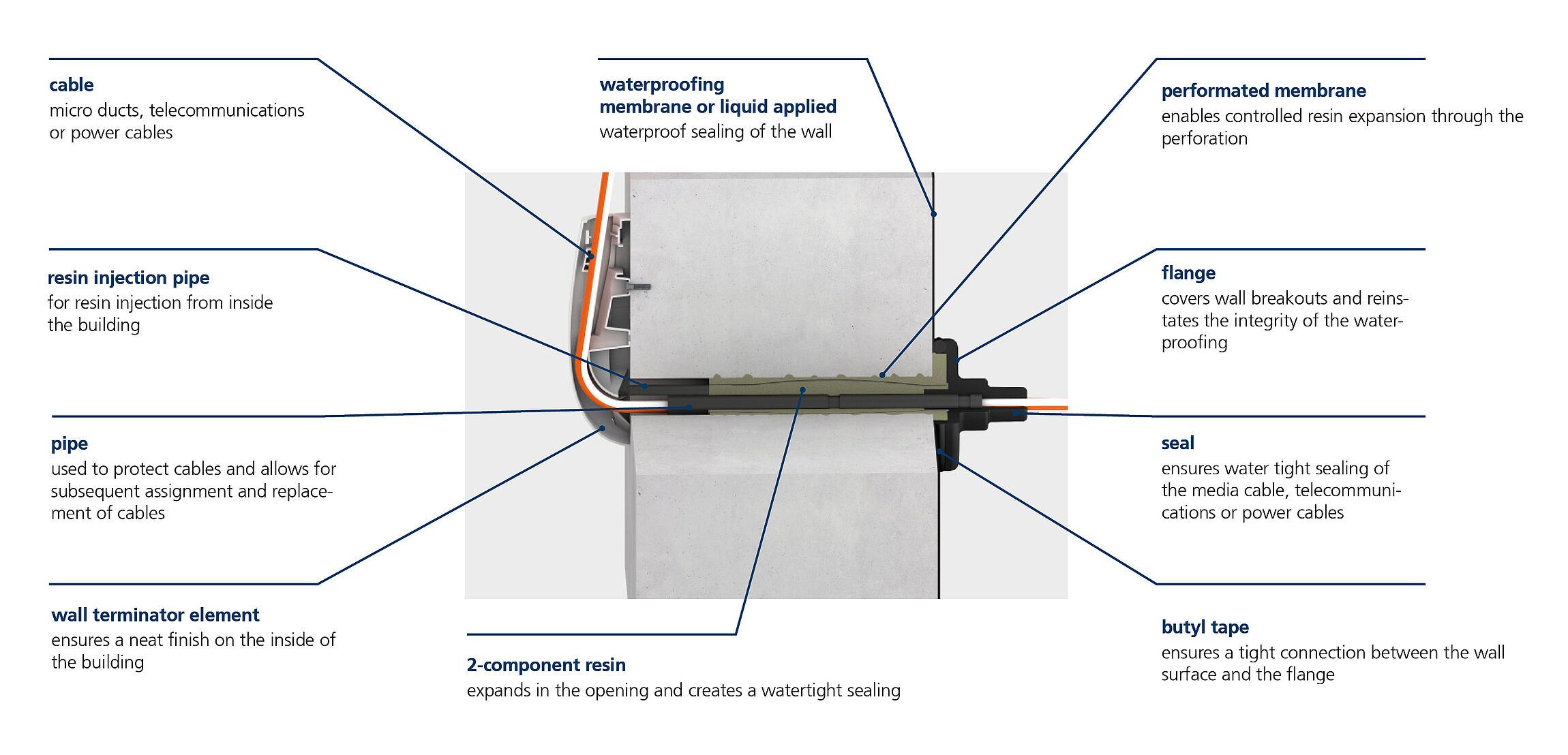

The use of the membrane injection system allows the escape of the expansion resin to be precisely controlled. The perforated membrane ensures that the resin expands in a definded space. This allows joints and breakouts to be repaired.

It applies to different types of walls: concrete walls, brick walls, etc. Without this membrane, the expansion resin would flow out uncontrollably, which would not ensure optimal sealing. The flange, which is attached to the outer wall, serves as a formwork aid to keep the expansion resin in the opening.

Conventional sealing foam

- uncontrolled expansion

- cable not centred

- not all spaces filled

Membrane injection system

- controlled injection

- resin amount reduced

- long-term sealing

Structure of the membrane injection system

Comparison with conventional sealing foams

Conventional expansion foams are often used in practice for sealing pipes and cables. These usually do not provide long-term sealing and are only effective for a short period of time. In addition, without formwork, they do not fill the spaces between the cables or the area between the cable/pipe and the wall opening that need to be sealed.

Scope of application of a membrane injection system

The MIS system offers a wide range of applications. It can be used in all common wall types and provides a sealing solution for a variety of cables and pipes in existing buildings. This also includes the standard diameters used for fibre optic microducts.

Advantages of a membrane injection system

MIS is a building entry point with a built-in injection membrane. This enables controlled resin injection and significantly reduces the installation time for a house connection.

Effective sealing: Even under high water pressure.

Retrofit application: Suitable for renovations without extensive construction work.

Durability: Long-term sealing effect.

Fibre optics

Membrane injection system

for buildings with a basement

MIS40DMembrane injection system

for buildings with a basement

MIS60NDFibre optics – Hauff-Technik GRIDCOM

Membrane injection system

for buildings with or without a basement

2LINE MIS25 PROPower

Membrane injection system

for buildings with a basement

MIS60DMembrane injection system

for buildings with a basement

MIS60D E SETMembrane injection system

for buildings with or without a basement

MIS60SMembrane injection system

for buildings without a basement

MIS60S E SETWater

Membrane injection system

for buildings with a basement

MIS90DMembrane injection system

for buildings with or without a basement

MIS90SGas

Membrane injection system

for buildings with or without a basement

MIS90SHelp us improve our website service.

Where would you place yourself?

Professional area

Architect & designer

Wholesaler

Telecoms

Utility company

Installer

Construction company

Private sector

Client

Applicant

Please choose your region

-

Belgium

Belgium

-

Česko

Česko

-

Danmark

Danmark

-

Deutschland

Deutschland

-

España

España

-

France

France

-

Global

Global

-

Hrvatska

Hrvatska

-

Italia

Italia

-

Luxembourg

Luxembourg

-

Magyarország

Magyarország

-

Nederland

Nederland

-

Österreich

Österreich

-

Polska

Polska

-

Schweiz

Schweiz

-

Slovenija

Slovenija

-

Slovensko

Slovensko

-

Sverige

Sverige

-

United Kingdom

United Kingdom

-

Global

Global

-

USA

USA

-

Global

Global

-

India

India

-

中国

中国

-

Global

Global

-

الإمارات العربية المتحدة

الإمارات العربية المتحدة